Marine Mechanical Governors – Ensuring Accurate Speed Control for Marine Engines

Marine mechanical governors are vital components used in propulsion and auxiliary engines to maintain constant engine speed under varying load conditions. Their primary purpose is to regulate fuel delivery automatically, ensuring stable, efficient, and safe engine performance at sea.

Marine Mechanical Governors – Ensuring Accurate Speed Control for Marine Engines

Marine mechanical governors are vital components used in propulsion and auxiliary engines to maintain constant engine speed under varying load conditions. Their primary purpose is to regulate fuel delivery automatically, ensuring stable, efficient, and safe engine performance at sea.

Operating Principle

Mechanical governors rely on a flyweight assembly driven directly by the engine through a gear mechanism. As the engine speed increases, centrifugal force causes the flyweights to move outward. This motion is counteracted by a calibrated speeder spring that pushes the flyweights toward their neutral position. The balance between the centrifugal force and spring tension determines the governor’s output.

The movement of the flyweights is transferred to a control sleeve or spindle, which adjusts the fuel pump racks.

- When load increases: Engine speed reduces → flyweights move inward → sleeve moves downward → fuel delivery increases → engine returns to set speed.

- When load decreases: Engine speed rises → flyweights move outward → sleeve moves upward → fuel delivery is reduced → engine stabilizes again.

This continuous feedback system ensures smooth speed regulation, preventing engine overspeed or underspeed conditions.

Advantages of Mechanical Governors

- Simple and robust construction

- Fast response to load changes

- Reliable performance without complex electronics

- Easy to maintain and adjust

- Ideal for marine engines with continuous load variations

Common Applications

- Main propulsion engines

- Auxiliary diesel generators

- Emergency engines

- Pump and compressor engines

Maintenance Practices

To ensure long service life and stable performance:

- Keep the governor free of dirty or thickened lubricating oil

- Perform regular flushing with the correct grade of oil

- Maintain proper oil level in the governor housin

- Avoid unnecessary adjustments or tampering

- Allow only trained personnel to service or calibrate the governor

Mechanical governors remain one of the most dependable speed control solutions for marine engines, offering unmatched reliability and simplicity—perfect for demanding shipboard environments.

Marine mechanical governors are vital components used in propulsion and auxiliary engines to maintain constant engine speed under varying load conditions. Their primary purpose is to regulate fuel delivery automatically, ensuring stable, efficient, and safe engine performance at sea.

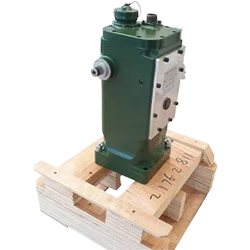

High-quality marine mechanical governors and spare parts ensuring precise engine speed control and reliable performance for all marine applications.

Marine Governors & Spare Parts

Sindhu Marine supplies a comprehensive range of Marine Mechanical and Hydraulic Governors for main and auxiliary engines. Our product range includes complete governor units and high-quality spare parts sourced from trusted global manufacturers.

Our Product Range Includes:

- Mechanical

- Governors

- Hydraulic Governors

- Governor Drive Gear

- Assemblies

- Speeder Springs

- Flyweight Assemblies

- Control Sleeves & Spindles

- Pilot Valves & Power Pistons

- Linkages & Racks

- Complete Repair Kits

Marine Mechanical Governors

Reliable, high-performance mechanical governors ensuring precise engine speed control for marine propulsion and auxiliary engines. Available with genuine and OEM spares for all major brands.